Study on welding fume particles of gas shielded welding in workplaces

-

+ English摘要:目的 研究作业场所气体保护焊焊接烟尘暴露特征,为作业场所电焊烟尘颗粒物健康危害评估与控制提供基础数据。方法 在实验测试空间中模拟焊接作业过程,分别在距离焊源50 cm(焊接人员作业位)和250 cm处(电焊辅助工作业位),检测焊接烟尘中颗粒物的粒径分布、数量浓度、质量浓度及其随距离及时间的变化情况,同时对烟尘进行采样,分析烟尘中金属元素含量及分布情况。结果 焊接150 s过程中,距离焊源50 cm处检测颗粒物总数量浓度为(72.50±16.55)×105个/cm3,其中超细颗粒物(颗粒直径 < 100 nm)约占60%;一旦焊接结束,数量浓度下降明显(P < 0.01),尤其是超细颗粒物下降显著,50 nm、100 nm、1 000 nm粒径通道颗粒物数量浓度下降率分别为94.45%、78.93%和50.63%;焊接中,距离焊源250 cm处检测的颗粒物数量浓度和PM1质量浓度相比本底值明显升高(P < 0.01),分别为本底值的45.84倍和2.9倍,最高数量浓度为(20.47±5.91)×105个/cm3,但低于50 cm处数量浓度值(P < 0.01);焊接烟尘中0.32~0.56 μm粒径的金属元素的质量浓度达到峰值,其中超细颗粒物质量分数是总金属元素的10.06%。结论 电焊作业能产生大量超细颗粒物;焊接烟尘金属及其化合物主要分布于细颗粒和超细颗粒电焊烟尘中,有可能发挥更高的潜在毒性。作业场所应加强局部通风,防止烟尘逸散,同时要加强电焊操作工和辅助工的个人防护和岗位监测。

-

焊接工艺普遍应用于装备制造、工程建设、建筑施工、交通运输和设备维修等诸多领域,气体保护焊作为一种高效焊接技术,是目前应用最广、发展速度最快的一种焊接方法。焊接过程中会产生高浓度气态和气溶胶产物,其包括金属颗粒、金属氧化物和其他化学成分。电焊烟尘可以引起电焊工尘肺、金属及其化合物粉尘肺沉着病、金属烟热、职业性锰中毒等多种职业病,并会引起劳动者免疫力降低、非特异性呼吸系统疾病等[1-2],2017年国际癌症研究机构将电焊烟尘列为人类致癌物质(第1类)[3]。

随着检测技术的发展,超细颗粒物对健康损害的相关研究也逐渐成为热点。研究表明,超细颗粒物对人体健康的影响还与化学结构、团聚状态、所带电荷,以及超细颗粒的表面修饰、表面活性密切相关,粒径越小其可能导致损伤的风险愈大[4]。电焊烟尘中颗粒粒径范围广泛,其中大量颗粒物直径 < 1 μm,极易被人体吸收[5]。目前,国外对电焊烟尘颗粒物的检测和评估逐渐成为热点,而国内的研究多集中在控制效果评价、电焊烟尘职业接触调查评估等方面,缺乏对电焊烟尘颗粒物暴露特征的基础研究[6]。因此,我们选择气体保护焊为研究对象,进一步分析电焊烟尘的粒径分布特征、化学成分、数量浓度与质量浓度,以及随时间、距离变化情况,以期为电焊烟尘颗粒物健康危害评估与防护提供基础数据。

1. 材料与方法

1.1 材料

二氧化碳气体保护焊(gas metal arc welding,GMAW,100%CO2);药芯气体保护焊丝(T711,中国华通),直径1.4 mm,焊接电流216 ~ 275 A,焊接电压25 ~ 30 V。

1.2 方法

1.2.1 检测指标及设备

本研究采用便携式扫描电迁移率颗粒粒径测量分析系统(GRIMM 530型,德国),由微分电迁移率分析仪(differential mobility analyzers,DMA)和冷凝粒子计数器(condensation particle counter,CPC)组成,DMA用于筛分不同电迁移率粒径的颗粒物,CPC用于测量颗粒物数量。该系统数量浓度检测范围1 ~ 107个/cm3,进气口流量0.3 L/min。以120 s测量周期测量5.11 ~ 350.53 nm之间颗粒的粒度分布,共23个通道粒径分布(5.11、6.08、7.24、8.63、10.28、12.25、14.61、17.44、20.83、24.90、29.80、35.72、42.88、51.59、62.24、75.35、91.62、112.00、137.85、171.11、214.58、272.40、350.53 nm)[7]。由于烟雾浓度很高,因此使用了气溶胶稀释器(GRIMM 1.159型,德国)来实现颗粒物的稀释,稀释比为100∶1。

使用气溶胶光谱仪(GRIMM 1109型,德国)对粒径为350 nm ~ 10 μm的颗粒进行测量。该设备通过光散射计数原理计算颗粒物数量浓度,检测粒径范围:250 nm ~ 32 μm,可检测数量浓度范围1个/L ~ 2 × 106个/L,流量1.2 L/min,每6 s记录1次。

同时使用便携式气溶胶光谱仪(GRIMM 1109型,德国),在检测焊接过程中实时检测PM1、PM2.5和PM10质量浓度。

设备准备:每次使用前,在洁净环境中使用设备自带调零滤膜进行调零,并对进样流量进行校正。使用后,对进气口管道进行清理。

1.2.2 检测方法

焊接实验测试空间:选择在一大型钢构制造厂房近入口通风处,远离作业区建搭4.0 m × 2.3 m × 2.3 m实验测试房,无窗及通风设施。焊接实验及测试均在此空间内进行,测试时关闭房门,以消除自然通风对测试结果的影响。

实验空间本底浓度检测:每次焊接实验开始前,完成实验空间内本底值的检测,检测时间10 min;每次实验结束后,开启自然通风和机械通风使室内颗粒物净化。

焊接实验:在实验空间内由工人进行150 s的焊接,然后停止焊接,分别检测焊接过程中距离焊源50 cm(焊接工人作业位)和距离焊源250 cm处(辅助工作业位)呼吸带高度焊接颗粒物平均数量浓度,并以150 s的间隔连续5次检测场所中焊接颗粒的粒径分布及平均数量浓度变化情况。同时测量不同检测距离质量浓度变化。实验重复3次。

1.2.3 颗粒物采样及成分分析

焊接过程中,使用微孔均匀沉积式碰撞采样器(MOUDI-125B,美国MSP公司),对粒径 < 10 μm的大气颗粒物分13级采样,标称切割直径分别为10 000、5 600、3 200、1 800、1 000、560、320、180、100、56、32、18和10 nm,使用石英滤膜(美国Millipore,直径47 mm)收集,采样时间为5 min,采样后,放入清洁的滤膜盒内,放置储存箱内运输和保存。使用电感耦合等离子体质谱(ICP-MS)法检测其锰、铜、铅等8种金属元素含量[8]。

1.2.4 统计学分析

检测数据以均数±标准差(x ± s)表示,采用SPSS 19.0软件进行统计分析,两组资料比较用t检验,组间差异比较采用单因素方差分析。两两比较,如方差齐时,采用LSD检验;若方差不齐时,采用Dunnet’s t检验。检验水准α = 0.05。

2. 结果

2.1 焊接过程中颗粒物数量浓度及粒径分布特征

焊接前,通过自然通风和机械排风后,测量实验空间内的颗粒物本底数量浓度为(0.40 ~ 0.57)× 105个/cm3。焊接过程中颗粒物数量浓度明显增加,50 cm检测点焊接150 s过程中颗粒物总数量浓度为(72.50 ± 16.55)× 105个/cm3,数量浓度呈单峰分布,主峰分布为90 ~ 110 nm,峰值浓度为(13.70 ± 2.89)× 105个/cm3。焊接过程中产生的超细颗粒物(直径 < 100 nm)约占总颗粒物数量的60%,50 nm以下颗粒物约占总量的20%。各粒径颗粒物累计浓度分布见表 1。

表 1 焊接过程中不同粒径颗粒物分布颗粒粒径①/nm 累计构成比/% 颗粒粒径①/nm 累计构成比/% 5.11 0 112.00 79.32 6.08 0 137.85 89.71 7.24 0 171.11 96.93 8.63 0 214.58 98.78 10.28 0.01 272.40 99.26 12.25 0.02 350.53 99.59 14.61 0.07 375 99.80 17.44 0.17 425 99.88 20.83 0.37 475 99.93 24.90 0.77 540 99.95 29.80 1.45 615 99.97 35.72 4.22 675 99.99 42.88 11.58 750 99.99 51.59 20.45 900 99.99 62.24 30.11 1 150 100 75.35 43.54 11 250 100 91.62 60.40 注:①粒径范围在5.11 ~ 350.53 nm的颗粒物由GRIMM 530型仪器测定,粒径范围375 ~ 11 250 nm的颗粒物由GRIMM 1109型仪器测定。 2.2 时间和空间对电焊烟尘颗粒物数量浓度及粒径分布的影响

从焊接开始时记录,每150 s为1次观察点,连续观察5次。在距离焊接点50 cm处的检测结果显示,焊接停止后,各时间点颗粒物总数量浓度差异有统计学意义(P < 0.001),表现为:随着时间间隔的增加,颗粒物总数量浓度降低,在焊接停止后第1个150 s内,平均数量浓度下降了约75%;但随着间隔时间的延长,颗粒浓度降低速度趋缓,焊接停止后第2个150 s、第3个150 s、第4个150 s各时间段间数量浓度差异无统计学意义(P > 0.05)。此过程中峰浓度粒径尺寸分布向较大的颗粒略微偏移。

焊接时,在距离焊接点250 cm处的检测结果显示,各时间点颗粒物总数量浓度差异有统计学意义(P < 0.01),表现为:总颗粒数量浓度先是增加,并在焊接后第1个150 s内达到峰值,但随后逐渐降低,与50 cm处各检测时间段总数量浓度比较,仅焊接过程中的数量浓度差异有统计学意义(P < 0.001),其余各时间间隔内数量浓度(焊接停止后第1 ~ 4个150 s)差异无统计学意义(P > 0.05)。见表 2。

表 2 不同时间和距离电焊烟尘颗粒物数量浓度的比较检测时间 50 cm检测点 250 cm检测点 总数量浓度/(× 105个/cm3) 浓度比值(CR)④ 峰值浓度/(× 105个/cm3) 峰值粒径/nm 总数量浓度/(× 105个/cm3) 浓度比值(CR) 峰值浓度/(× 105个/cm3) 峰值粒径/nm 焊接前本底 0.57 ± 0.05 0.07 ± 0.02 113.82 ± 23.17 0.40 ± 0.19 0.05 ± 0.02 52.73 ± 11.21 焊接150s过程中 72.50 ± 16.55① 127.85 ± 33.81 13.70 ± 2.89 92.99 ± 18.30 1.72 ± 1.30 ① 4.95 ± 1.35 0.39 ± 0.16 59.64 ± 14.41 焊接后第1个150 s 18.23 ± 8.60①② 31.23 ± 11.90 3.74 ± 2.38 101.81 ± 14.41 20.47 ± 5.91①② 45.84 ± 20.30 3.75 ± 1.26 91.62 ± 0.01 焊接后第2个150 s 8.75 ± 1.93①② 15.19 ± 2.36 1.41 ± 0.31 105.21 ± 11.77 8.83 ± 1.69①②③ 19.58 ± 6.76 1.28 ± 0.32 105.21 ± 11.77 焊接后第3个150 s 5.77 ± 1.14①② 10.04 ± 1.45 0.87 ± 0.24 120.62 ± 14.92 5.73 ± 0.78①②③ 12.63 ± 3.62 0.76 ± 0.18 140.32 ± 19.63 焊接后第4个150 s 4.31 ± 0.66①②③ 7.53 ± 1.03 0.58 ± 0.12 140.32 ± 12.69 4.39 ± 0.40①②③ 9.63 ± 2.36 0.54 ± 0.15 131.70 ± 24.13 F值 35.231 19.906 P值 < 0.001 < 0.001 注:总数量浓度为3次重复实验的平均值。①与本底值比较,P < 0.01;②与该距离焊接中浓度比较,P < 0.01;③与该距离中焊接后第1个150 s比较,P < 0.01;④CR值指与该距离的本底浓度的比值。 50、100、1 000 nm粒径颗粒物数量浓度在各时间点的差异均有统计学意义(P < 0.01),表现为:在焊接后第1个150 s,50 nm和100 nm粒径通道颗粒物数量浓度显著下降,下降率达到94.45%和78.96%;1 000 nm附近颗粒物数量浓度下降50.63%。随着间隔时间的延长,颗粒物数量浓度变化趋缓。见表 3。

表 3 典型粒径颗粒物数量浓度随时间分布情况检测时间 50 nm粒径 100 nm粒径 1 000 nm粒径 数量浓度/(× 105个/cm3) 下降率/%③ 数量浓度/(× 105个/cm3) 下降率/%③ 数量浓度/(个/cm3) 下降率/%③ 焊接前本底 0.04 ± 0.02 0.06 ± 0.01 21.38 ± 8.04 焊接150 s过程中 5.71 ± 0.54① 13.70 ± 2.88① 87.30 ± 34.74① 焊接后第1个150 s 0.32 ± 0.04①② 94.45 2.88 ± 0.75①② 78.96 43.10 ± 4.59①② 50.63 焊接后第2个150 s 0.15 ± 0.05①② 53.79 1.26 ± 0.08①② 56.42 41.23 ± 5.26①② 4.33 焊接后第3个150 s 0.14 ± 0.03①② 1.32 0.65 ± 0.07①② 48.53 39.33 ± 6.23①② 4.61 焊接后第4个150 s 0.13 ± 0.03①② 8.93 0.38 ± 0.03①② 41.91 40.30 ± 5.28①② - 2.47 F值 315.181 57.260 6.278 P值 < 0.001 < 0.001 0.004 注:数量浓度为3次重复实验的平均值。①与本底值比较,P < 0.01;②与该距离焊接中浓度比较,P < 0.01;③与前一个检测时间点浓度均值的比值-1。 2.3 不同检测距离对电焊烟尘质量浓度的影响

焊接过程中,PM1、PM2.5及PM10各组在焊接前本底、焊接中50 cm处、焊接中250 cm处比较,差异均具有统计学意义(P < 0.01)。进一步两两比较,均以焊接中50 cm位置处的质量浓度最高,焊接前本底值最低(P < 0.01)。见表 4。

表 4 不同距离PM1、PM2.5、PM10检测结果检测距离 样本量 PM10 PM2.5 PM1 质量浓度/(μg/m3) 浓度变化倍数③ 质量浓度/(μg/m3) 浓度变化倍数③ 质量浓度/(μg/m3) 浓度变化倍数③ 焊接前本底 25 337.15 ± 87.08 214.18 ± 28.38 165.02 ± 16.05 焊接中50 cm处 25 817.22 ± 149.32① 2.42 638.25 ± 144.75① 2.98 560.38 ± 126.75① 3.40 焊接中250 cm处 25 640.11 ± 49.45② 1.90 520.01 ± 38.82② 2.43 478.72 ± 40.65② 2.90 F值 395.595 437.692 513.512 P值 < 0.001 < 0.001 < 0.001 注:①与本底值比较,P < 0.01;②与50 cm处浓度比较,P < 0.01;③与焊接前本底浓度均数的比值。 2.4 电焊烟尘中金属元素分布情况

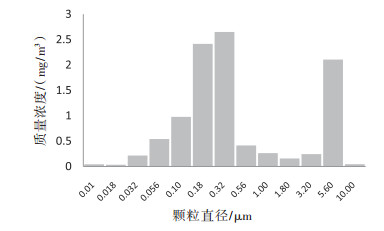

本次所检测的8种金属元素质量浓度呈双峰分布,0.32 ~ 0.56 μm和5.6 ~ 10 μm粒径的烟尘中金属出现两个浓度峰值(见图 1)。各类金属质量分数从大到小依次为Fe > Mn > Zn > Ti > Ni > Cu > Cr > Pb(见表 5),其中Fe和Mn含量最高,质量分数分别占所检测金属总量的45.16%和31.90%。结果同时显示61.29%的所检金属分布在0.10 ~ < 1.00 μm的粒径组中;0.01 ~ < 0.10 μm组和1.00 ~ 10.00 μm组中金属元素质量分数分别占总量的10.06%、28.66%,值得关注的是75.72%的Ni金属颗粒为超细颗粒(颗粒直径 < 100 nm)。

表 5 不同粒径组典型重金属分布情况 (占比/%)金属元素 粒径0.01 ~ < 0.10 μm 粒径0.10 ~ < 1.00 μm 粒径1.00 ~ 10.00 μm 总计 Fe 9.83 62.07 28.09 45.16 Mn 6.92 65.11 27.97 31.90 Zn 5.72 67.03 27.26 18.29 Ti 4.74 66.47 28.79 4.09 Ni 75.72 16.16 8.13 0.39 Cu 31.11 38.24 30.66 0.10 Cr 23.64 55.70 20.66 0.05 Pb 39.02 42.14 18.85 0.02 各粒径组合计 10.06 61.29 28.66 100 3. 讨论

药芯焊丝气保焊(FCAW-G)是一种应用非常广泛的焊接工艺,由于其具有工艺性好、焊缝质量好等优点,逐渐替代了实心焊丝,用量逐渐增大,故劳动者接触人数众多。在发达国家,电焊烟尘研究得到高度重视,电焊烟尘致病机制的研究已相对成熟,2011年后,国际电焊烟尘的研究逐步进入以颗粒物研究为主的阶段,如超细颗粒毒性标志物以及检测评估方法等[9-11]。研究发现,传统的质量浓度不能真实反映超细颗粒的剂量-反应关系,数量和表面积浓度较质量浓度能更准确地评估工作场所纳米颗粒暴露水平[12]。同时,电焊烟尘对工人造成的不良健康后果,例如肺纤维化、线粒体损伤、DNA损伤、肺癌和哮喘,多与高水平的细小或纳米级颗粒物接触有关[13]。

Antonini等[9]研究发现焊接中所产生的颗粒物暴露特征与焊接方法、焊丝材料、焊接电压和焊条消耗速度等因素有关。Brand等[10]研究了6种不同焊接工艺,平均颗粒物数量浓度范围为2.0 × 106 ~ 5.1 × 107个/cm3。在本次研究中,对气体保护焊(药芯焊丝,100%CO2)的焊接烟尘进行研究,发现在距离焊源50 cm处检测到的颗粒物数量浓度为(72.50 ± 16.55)× 105个/cm3,高于Cena等[14]对实芯气保焊ER70S-3(低合金钢焊丝)的研究结果,后者在30 cm处测得颗粒物数量浓度为2.7 × 106个/cm3,这可能与焊接时间和焊丝类型不同有关。闫红[15]对直流MIG焊、脉冲MIG焊、药芯焊丝CO2气体保护焊、实心焊丝CO2气体保护焊4种焊接工艺进行比较,也发现药芯焊丝CO2气体保护焊发尘量高于其他焊种。同时在本次研究中,发现气体保护焊(药芯焊丝)焊接过程中产生的颗粒物约60%为超细颗粒物。该比例与Brand等[10]的研究结果(54%)相近。超细颗粒物的小尺寸效应以及高表面活性等特点,会使气体保护焊(药芯焊丝)产生的颗粒更容易沉积于肺泡内,产生更多的毒理学活性。

本次实验也进一步分析了焊接中产生的颗粒物的时间变化。在距离焊源50 cm处观察到,一旦焊接过程停止,颗粒物浓度就显著下降,对于超细颗粒尤其如此。因为这些颗粒会凝结在较大的颗粒上,尺寸分布向较大的颗粒略微偏移。在密闭空间内,风速几乎为0,随着时间的增加,数量浓度下降速度趋于缓慢,在焊接后600 s后,空气中的颗粒物浓度是未焊接前的7.53倍,颗粒峰值粒径在(140.32 ± 12.69)nm并较长时间悬浮在空气中。在电弧焊过程中,焊接颗粒物主要是由于冷却过程中极热蒸气的冷凝而形成的。Preining研究发现焊接中初始粒子数量浓度非常高,半衰期极短[16],随着焊接停止或温度降低,初始粒子发生了不同程度的凝并和聚集,形成“二次粒子”,随着粒径的增加和数量浓度的降低,此过程逐渐变缓,当“二次粒子”直径约为100 ~ 400 nm时,在凝并和聚集过程中,固有颗粒运动几乎停止。提示在通风不良的情况下,尤其是密闭空间焊接作业,电焊烟尘将长期悬浮在空气中。

本次实验分别检测了距离焊源50 cm(焊工作业位)和距离焊源250 cm(周边辅助工作业位)呼吸带高度浓度。焊接过程中,辅助工作业位的颗粒物浓度也明显上升,数量浓度上升至45.84倍,质量浓度(PM1)上升至2.9倍。同时,在焊工作业位的总颗粒物数量浓度和质量浓度分别是辅助工作业位最高浓度的3.5倍(72.5 /20.47)和1.2倍(560.38/478.72),提示焊接颗粒物浓度与检测距离相关,颗粒物数量浓度和质量浓度的空间分布与颗粒的扩散、凝聚与沉积特性有关[5]。因此,不仅要关注电焊操作工的暴露量,而且还要关注附近工人的暴露量和防护。

焊接烟尘中含有大量金属化合物,其成分与焊材及焊芯成分密切相关,也是电焊烟尘毒作用的主要来源。Hewett研究指出焊接烟尘中金属成分的分布与质量分布相似[17],本次实验分析了焊接烟尘中金属成分,发现金属及其化合物粒径主要分布在0.32 ~ 0.56 μm,超细颗粒物质量分数占总金属元素的10.06%,与国内宾平凡等[5]研究的电焊作业车间焊接烟尘颗粒物质量浓度分布结果相似。YANG等[18]研究发现电焊烟尘中的金属在水中的溶解能力与金属种类有关,也与颗粒大小有关。本次研究发现,虽然超细颗粒物总质量分数较小,但电焊烟尘中约60%的颗粒物为超细颗粒物,且较高比例的Ni金属及其化合物粒径小于100 nm,故提示可能会有更高的细胞毒性和健康损害[19-20]。

综上所述,焊接作业中产生大量的颗粒物,其中超细颗粒物数量占比较高,对电焊烟尘危害的预防控制需要进一步考虑到对超细颗粒的防护。建议加强低毒、低尘焊材的研制和应用推广;提高焊接技术,实现焊接操作的机械化、自动化。针对超细颗粒物可随周围气流运动的特点,建议选择适宜的通风除尘工艺,可通过用带有高效空气颗粒过滤装置的排风通气系统,提升烟尘捕集效率,如使用移动式排烟罩、离子荷电就地抑制除尘技术等[21-22]。同时应关注焊接作业周围工人暴露评估与防护,加强作业及周边人员的个体防护。个体防护用品的选择与佩戴方式的准确性直接影响防护效率,故应加强对接害员工的培训和教育。

另外,焊接烟尘中的多种金属及其化合物主要属于细颗粒和超细颗粒,其中的超细金属颗粒有可能发挥更高的潜在毒性,须进一步加强对其健康危害的评估及控制研究。

作者声明 本文无实际或潜在的利益冲突 -

表 1 焊接过程中不同粒径颗粒物分布

颗粒粒径①/nm 累计构成比/% 颗粒粒径①/nm 累计构成比/% 5.11 0 112.00 79.32 6.08 0 137.85 89.71 7.24 0 171.11 96.93 8.63 0 214.58 98.78 10.28 0.01 272.40 99.26 12.25 0.02 350.53 99.59 14.61 0.07 375 99.80 17.44 0.17 425 99.88 20.83 0.37 475 99.93 24.90 0.77 540 99.95 29.80 1.45 615 99.97 35.72 4.22 675 99.99 42.88 11.58 750 99.99 51.59 20.45 900 99.99 62.24 30.11 1 150 100 75.35 43.54 11 250 100 91.62 60.40 注:①粒径范围在5.11 ~ 350.53 nm的颗粒物由GRIMM 530型仪器测定,粒径范围375 ~ 11 250 nm的颗粒物由GRIMM 1109型仪器测定。 表 2 不同时间和距离电焊烟尘颗粒物数量浓度的比较

检测时间 50 cm检测点 250 cm检测点 总数量浓度/(× 105个/cm3) 浓度比值(CR)④ 峰值浓度/(× 105个/cm3) 峰值粒径/nm 总数量浓度/(× 105个/cm3) 浓度比值(CR) 峰值浓度/(× 105个/cm3) 峰值粒径/nm 焊接前本底 0.57 ± 0.05 0.07 ± 0.02 113.82 ± 23.17 0.40 ± 0.19 0.05 ± 0.02 52.73 ± 11.21 焊接150s过程中 72.50 ± 16.55① 127.85 ± 33.81 13.70 ± 2.89 92.99 ± 18.30 1.72 ± 1.30 ① 4.95 ± 1.35 0.39 ± 0.16 59.64 ± 14.41 焊接后第1个150 s 18.23 ± 8.60①② 31.23 ± 11.90 3.74 ± 2.38 101.81 ± 14.41 20.47 ± 5.91①② 45.84 ± 20.30 3.75 ± 1.26 91.62 ± 0.01 焊接后第2个150 s 8.75 ± 1.93①② 15.19 ± 2.36 1.41 ± 0.31 105.21 ± 11.77 8.83 ± 1.69①②③ 19.58 ± 6.76 1.28 ± 0.32 105.21 ± 11.77 焊接后第3个150 s 5.77 ± 1.14①② 10.04 ± 1.45 0.87 ± 0.24 120.62 ± 14.92 5.73 ± 0.78①②③ 12.63 ± 3.62 0.76 ± 0.18 140.32 ± 19.63 焊接后第4个150 s 4.31 ± 0.66①②③ 7.53 ± 1.03 0.58 ± 0.12 140.32 ± 12.69 4.39 ± 0.40①②③ 9.63 ± 2.36 0.54 ± 0.15 131.70 ± 24.13 F值 35.231 19.906 P值 < 0.001 < 0.001 注:总数量浓度为3次重复实验的平均值。①与本底值比较,P < 0.01;②与该距离焊接中浓度比较,P < 0.01;③与该距离中焊接后第1个150 s比较,P < 0.01;④CR值指与该距离的本底浓度的比值。 表 3 典型粒径颗粒物数量浓度随时间分布情况

检测时间 50 nm粒径 100 nm粒径 1 000 nm粒径 数量浓度/(× 105个/cm3) 下降率/%③ 数量浓度/(× 105个/cm3) 下降率/%③ 数量浓度/(个/cm3) 下降率/%③ 焊接前本底 0.04 ± 0.02 0.06 ± 0.01 21.38 ± 8.04 焊接150 s过程中 5.71 ± 0.54① 13.70 ± 2.88① 87.30 ± 34.74① 焊接后第1个150 s 0.32 ± 0.04①② 94.45 2.88 ± 0.75①② 78.96 43.10 ± 4.59①② 50.63 焊接后第2个150 s 0.15 ± 0.05①② 53.79 1.26 ± 0.08①② 56.42 41.23 ± 5.26①② 4.33 焊接后第3个150 s 0.14 ± 0.03①② 1.32 0.65 ± 0.07①② 48.53 39.33 ± 6.23①② 4.61 焊接后第4个150 s 0.13 ± 0.03①② 8.93 0.38 ± 0.03①② 41.91 40.30 ± 5.28①② - 2.47 F值 315.181 57.260 6.278 P值 < 0.001 < 0.001 0.004 注:数量浓度为3次重复实验的平均值。①与本底值比较,P < 0.01;②与该距离焊接中浓度比较,P < 0.01;③与前一个检测时间点浓度均值的比值-1。 表 4 不同距离PM1、PM2.5、PM10检测结果

检测距离 样本量 PM10 PM2.5 PM1 质量浓度/(μg/m3) 浓度变化倍数③ 质量浓度/(μg/m3) 浓度变化倍数③ 质量浓度/(μg/m3) 浓度变化倍数③ 焊接前本底 25 337.15 ± 87.08 214.18 ± 28.38 165.02 ± 16.05 焊接中50 cm处 25 817.22 ± 149.32① 2.42 638.25 ± 144.75① 2.98 560.38 ± 126.75① 3.40 焊接中250 cm处 25 640.11 ± 49.45② 1.90 520.01 ± 38.82② 2.43 478.72 ± 40.65② 2.90 F值 395.595 437.692 513.512 P值 < 0.001 < 0.001 < 0.001 注:①与本底值比较,P < 0.01;②与50 cm处浓度比较,P < 0.01;③与焊接前本底浓度均数的比值。 表 5 不同粒径组典型重金属分布情况 (占比/%)

金属元素 粒径0.01 ~ < 0.10 μm 粒径0.10 ~ < 1.00 μm 粒径1.00 ~ 10.00 μm 总计 Fe 9.83 62.07 28.09 45.16 Mn 6.92 65.11 27.97 31.90 Zn 5.72 67.03 27.26 18.29 Ti 4.74 66.47 28.79 4.09 Ni 75.72 16.16 8.13 0.39 Cu 31.11 38.24 30.66 0.10 Cr 23.64 55.70 20.66 0.05 Pb 39.02 42.14 18.85 0.02 各粒径组合计 10.06 61.29 28.66 100 -

[1] 路艳艳, 徐承敏, 钱亚玲. 电焊烟职业危害的一些研究进展[J]. 中华劳动卫生职业病杂志, 2015, 33(1): 65-68. doi: 10.3760/cma.j.issn.1001-9391.2015.01.023 [2] KIM J Y, CHEN J C, BOYCE P D, et al. Exposure to welding fumes is associated with acute systemic inflammatory responses[J]. Occup Environ Med, 2005, 62(3): 157-63. doi: 10.1136/oem.2004.014795

[3] GUHA N, LOOMIS D, GUYTON K Z, et al. Carcinogenicity of welding, molybdenum trioxide, and indium tin oxide[J]. Lancet Oncol, 2017, 18(5): 581-582. doi: 10.1016/S1470-2045(17)30255-3

[4] STOLZEL M, BREITNER S, CYRYS J, et al. Daily mortality and particulate matter in different size classes in Erfurt, Germany[J]. J Expo Sci Environ Epidemiol, 2007, 17(5): 458-467. doi: 10.1038/sj.jes.7500538

[5] 宾平凡, 张美辨, 陈苘, 等. 电焊工作场所超细颗粒与细颗粒暴露特征研究[J]. 浙江预防医学, 2012, 24(2): 8-12. doi: 10.3969/j.issn.1007-0931.2012.02.003 [6] 张雪娟, 樊晶光. 基于知识图谱的电焊烟尘研究可视化分析[J]. 环境与职业医学, 2018, 35(10): 917-923. https://www.cnki.com.cn/Article/CJFDTOTAL-LDYX201810009.htm [7] BRAND P, HAVLICEK P, STEINERS M, et al. Exposure of healthy subjects with emissions from a gas metal arc welding process: part 1-exposure technique and external exposure[J]. Int Arch Occup Environ Health, 2013, 86(1): 25-30. doi: 10.1007/s00420-012-0739-7

[8] 杜航, 龚进, 杨福成, 等. 电焊作业场所空气中10种金属元素的检测分析[J]. 中国卫生检验杂志, 2018, 28(3): 279-282 https://www.cnki.com.cn/Article/CJFDTOTAL-ZWJZ201803007.htm [9] ANTONINI J M, KEANE M, CHEN B T, et al. Alterations in welding process voltage affect the generation of ultrafine particles, fume composition, and pulmonary toxicity[J]. Nanotoxicology, 2011, 5(4): 700-710. doi: 10.3109/17435390.2010.550695

[10] BRAND P, LENZ K, REISGEN U, et al. Number size distribution of fine and ultrafine fume particles from various welding processes[J]. Ann Occup Hyg, 2013, 57(3): 305-313. http://www.ncbi.nlm.nih.gov/pubmed/23028013

[11] BRAND P, BISCHOF K, SIRY L, et al. Exposure of healthy subjects with emissions from a gas metal arc welding process: part 3-biological effect markers and lung function[J]. Int Arch Occup Environ Health, 2013, 86(1): 39-45. doi: 10.1007/s00420-012-0740-1

[12] 邹华, 张美辨, 邢鸣鸾, 等. 工作场所纳米颗粒暴露测量指标适用性研究[J]. 浙江预防医学, 2014, 26(4): 325-329. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYFX201404002.htm [13] CHANG C, DEMOKRITOU P, SHAFER M, et al. Physicochemical and toxicological characteristics of welding fume derived particles generated from real time welding processes[J]. Environ Sci Process Impacts, 2013, 15(1): 214-224. doi: 10.1039/C2EM30505D

[14] CENA L G, CHEN B T, KEANE M J. Evolution of welding-fume aerosols with time and distance from the source: a study was conducted on the spatiotemporal variability in welding-fume concentrations for the characterization of first- and second-hand exposure to welding fumes[J]. Weld J, 2016, 95(Suppl 1): 280-285. http://www.zhangqiaokeyan.com/academic-journal-foreign-pmc_detail_thesis/040005418037.html

[15] 闫红. 气体保护焊参数与焊接烟尘产生的关系[J]. 焊接技术, 2009, 38(9): 25-27. https://www.cnki.com.cn/Article/CJFDTOTAL-HSJJ200909009.htm [16] PREINING O. The physical nature of very, very small particles and its impact on their behaviour[J]. J Aerosol Sci, 1998, 29(5/6): 481-495. http://www.sciencedirect.com/science/article/pii/S0021850297100465

[17] HEWETT P. The particle size distribution, density, and specific surface area of welding fumes from SMAW and GMAW mild and stainless steel consumables[J]. Am Ind Hyg Assoc J, 1995, 56(2): 128-135. doi: 10.1080/15428119591017150

[18] YANG S Y, LIN J M, YOUNG L H, et al. Mass-size distribution and concentration of metals from personal exposure to arc welding fume in pipeline construction: a case report[J]. Ind Health, 2018, 56(4): 356-363. doi: 10.2486/indhealth.2017-0197

[19] FALCONE L M, ERDELY A, SALMEN R, et al. Pulmonary toxicity and lung tumorigenic potential of surrogate metal oxides in gas metal arc welding-stainless steel fume: iron as a primary mediator versus chromium and nickel[J]. PLoS One, 2018, 13(12): e0209413. doi: 10.1371/journal.pone.0209413

[20] MCCARRICK S, WEI Z, MOELIJKER N, et al. High variability in toxicity of welding fume nanoparticles from stainless steel in lung cells and reporter cell lines: the role of particle reactivity and solubility[J]. Nanotoxicol, 2019, 13(10): 1293-1309. doi: 10.1080/17435390.2019.1650972

[21] 黄靖雯, 沈安丽, 张战赛. 电焊烟尘危害及防控措施[J]. 职业卫生与应急救援, 2015, 33(1): 22-25. doi: 10.16369/j.oher.issn.1007-1326.2015.01.007 [22] 王雷, 张定成, 杨贵荣. 某铁路车辆焊接检修车间烟尘治理探讨[J]. 中国工业医学杂志, 2020, 33(4): 353-355. https://www.cnki.com.cn/Article/CJFDTOTAL-SOLE202004027.htm -

期刊类型引用(4)

1. 张文志,李红. 工业厂房内焊接烟尘流场模拟. 中国环保产业. 2024(05): 62-65 .  百度学术

百度学术

2. 王大宇,张慧庆,曾强. 电焊烟尘职业健康监护现状与研究进展. 中华劳动卫生职业病杂志. 2023(01): 66-71 .  百度学术

百度学术

3. 何嘉玉,吕向裴,齐放,于维松,余晨,陈艳霞,王焕强. 508名男性电焊工人肺功能水平及其影响因素分析. 中国工业医学杂志. 2022(02): 119-123 .  百度学术

百度学术

4. 臧静,魏振江,孙瑞霞. 石化钻井行业工程服务公司职业病危害调查与现状评价. 职业与健康. 2022(21): 2885-2888 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: